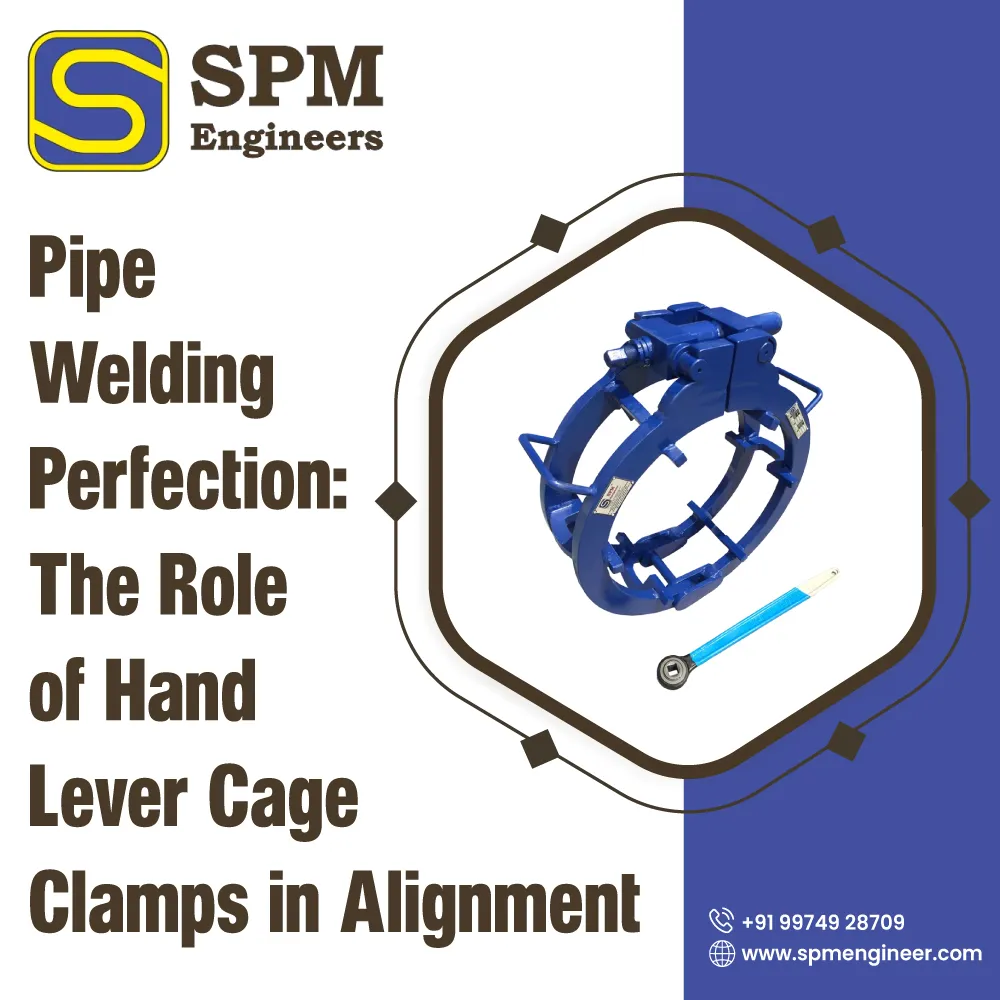

Precision in pipeline welding defines the success and safety of every project. Whether in oil and gas infrastructure, power generation, or water supply systems, accurate pipe alignment is vital to achieving seamless weld joints. A single misalignment during welding can lead to leaks, cracks, and costly repairs later. To overcome these challenges, industries rely on a specialized alignment solution — the Hand Lever Cage Clamp. This simple yet powerful mechanical device is essential for achieving perfect pipe alignment before and during welding.

At SPM Engineers, we manufacture high-performance hand lever cage clamps designed for industrial precision, durability, and ease of use. These clamps play a crucial role in the setup phase of pipeline welding, making them indispensable pipe welding alignment tools for professionals across the world.

What Is a Hand Lever Cage Clamp?

A Hand Lever Cage Clamp is a mechanical alignment tool used to hold two pipe ends together in the correct position before welding. Its cage-style construction ensures that the pipes are clamped securely and evenly across the circumference. The hand lever mechanism allows quick tightening and release, making it ideal for field use where speed and accuracy are critical.

These manual pipe alignment clamps are commonly used in industries that demand precise pipeline fit-up — including oil and gas, refineries, petrochemical plants, water transmission systems, and construction sites. Built from high-strength alloy materials, SPM Engineers’ hand lever cage clamps offer long-lasting performance even in harsh environmental conditions. Their simplicity, portability, and accuracy make them a must-have pipeline welding equipment for any industrial welding setup.

How Does a Hand Lever Cage Clamp Work?

The working principle of a hand lever cage clamp is based on controlled mechanical pressure applied through a hand lever system. Here’s a simple overview of its operation:

- Positioning: The clamp is placed around the two pipe ends that need to be joined.

- Adjustment: The hand lever is used to tighten the clamp evenly, aligning the pipe ends along the same axis.

- Locking: The cage structure holds the pipes firmly in place while welders perform tack welding.

- Release: Once the tack weld is complete, the lever is released, and the clamp is removed for the next section.

This process allows welders to maintain a uniform root gap, ideal weld angle, and accurate joint positioning. The result — perfect pipe welding alignment with minimal effort.

Key Features of SPM Engineers’ Hand Lever Cage Clamp

SPM Engineers manufactures high-quality hand lever cage clamps that combine functionality, durability, and safety. Each clamp is carefully engineered to deliver long-term performance in demanding environments. Some of the top features include:

- Durable Construction: Made from high-grade steel for long service life and strength under heavy loads.

- Quick-Action Lever Mechanism: Provides fast tightening and release, improving operational efficiency.

- Accurate Alignment: The cage structure offers full circumferential support for precise pipe centering.

- Portable Design: Lightweight and easy to handle, ideal for field welding operations.

- Corrosion Resistance: Coated for protection against rust, moisture, and heat.

- Multiple Size Compatibility: Available for a wide range of pipe diameters, from small to large pipelines.

When you invest in SPM Engineers’ manual pipe alignment clamp, you’re choosing reliability, precision, and performance trusted by professionals worldwide.

Applications of Hand Lever Cage Clamps

The hand lever cage clamp is widely used across industries that demand accurate pipe alignment. Some of the major applications include:

- Oil and Gas Pipelines: For aligning large-diameter pipes during cross-country pipeline installation.

- Petrochemical & Refinery Projects: Used for heavy-duty pipe alignment during complex weld joints.

- Water Transmission Systems: Helps in constructing long-distance water supply pipelines.

- Power Plants & Energy Projects: Used in high-pressure piping systems where precision is essential.

- Fabrication Workshops: For assembling pipe sections before welding.

From field installations to controlled fabrication environments, SPM Engineers’ pipeline welding equipment offers unmatched accuracy and speed.

Benefits of Using Hand-Lever Cage Clamps

Using a hand lever cage clamp in your pipeline projects offers numerous technical and operational advantages:

- Superior Pipe Alignment – The clamp ensures perfect axial and angular alignment between pipe ends, minimizing welding distortion and improving joint integrity.

- Time Efficiency – Quick lever operation reduces setup time, allowing faster tack welding and higher daily productivity.

- Enhanced Welding Quality – Uniform pressure from the cage clamp for pipeline welding eliminates gaps or mismatched joints, improving weld strength and reducing rework.

- Lightweight & Portable – Compact design allows easy transportation and handling during field operations.

- Cost Savings – Better weld quality and faster alignment translate into fewer reworks and reduced labor costs.

Each of these benefits makes the hand lever cage clamp an essential part of any professional welding toolkit.

Why Accurate Pipe Alignment Matters

Welding success begins with perfect alignment. Improperly aligned pipes can cause welding defects such as undercuts, misalignment gaps, or poor root fusion. These problems weaken the entire pipeline structure and may lead to failures under pressure. The manual pipe alignment clamp helps eliminate these risks by holding pipes firmly in place during the welding process. Consistent alignment improves weld penetration, reduces residual stress, and promotes long-term durability — key factors in industrial pipeline performance. Therefore, for welders who value precision and speed, the hand lever cage clamp becomes an indispensable part of daily operations.

Maintenance Tips for Long-Term Performance

Proper maintenance extends the lifespan of your hand lever cage clamp and ensures consistent performance on every project. Follow these steps to keep your equipment in top condition:

- Clean the clamp after every use to remove dirt and debris.

- Apply lubricants to moving parts for smooth operation.

- Inspect the lever mechanism regularly for wear or damage.

- Store the clamp in a dry area to prevent rust.

- Avoid over-tightening to maintain the structural integrity of the cage.

Routine care guarantees maximum efficiency and reliability for years of usage.

Why Choose SPM Engineers

SPM Engineers stands as a trusted name in pipeline welding equipment, delivering world-class solutions for alignment, handling, and welding applications. Our hand lever cage clamps are built using precision-engineered components and advanced manufacturing processes to deliver the highest quality results. With decades of industry experience, SPM Engineers is known for producing durable, high-performance pipe welding alignment tools that meet global standards. We are dedicated to supporting contractors, fabricators, and industrial clients with equipment that enhances accuracy, efficiency, and safety. When you choose SPM Engineers, you are choosing quality, reliability, and technical excellence that powers successful pipeline construction projects worldwide.

Conclusion

The Hand Lever Cage Clamp is the cornerstone of accurate and efficient pipeline welding. Its precision alignment capabilities make it an essential tool for achieving high-quality, uniform weld joints across industrial applications. From quick field setups to heavy-duty construction projects, the hand lever cage clamp simplifies welding alignment, enhances accuracy, and improves productivity. Backed by SPM Engineers’ proven engineering expertise and global reputation, this tool guarantees performance that meets the demands of modern pipeline projects.

For more information about Hand Lever Cage Clamps and related pipeline welding equipment, contact SPM Engineers today and experience precision welding at its best. Call us at +91 9974928709 or email us at info@spmengineer.com.