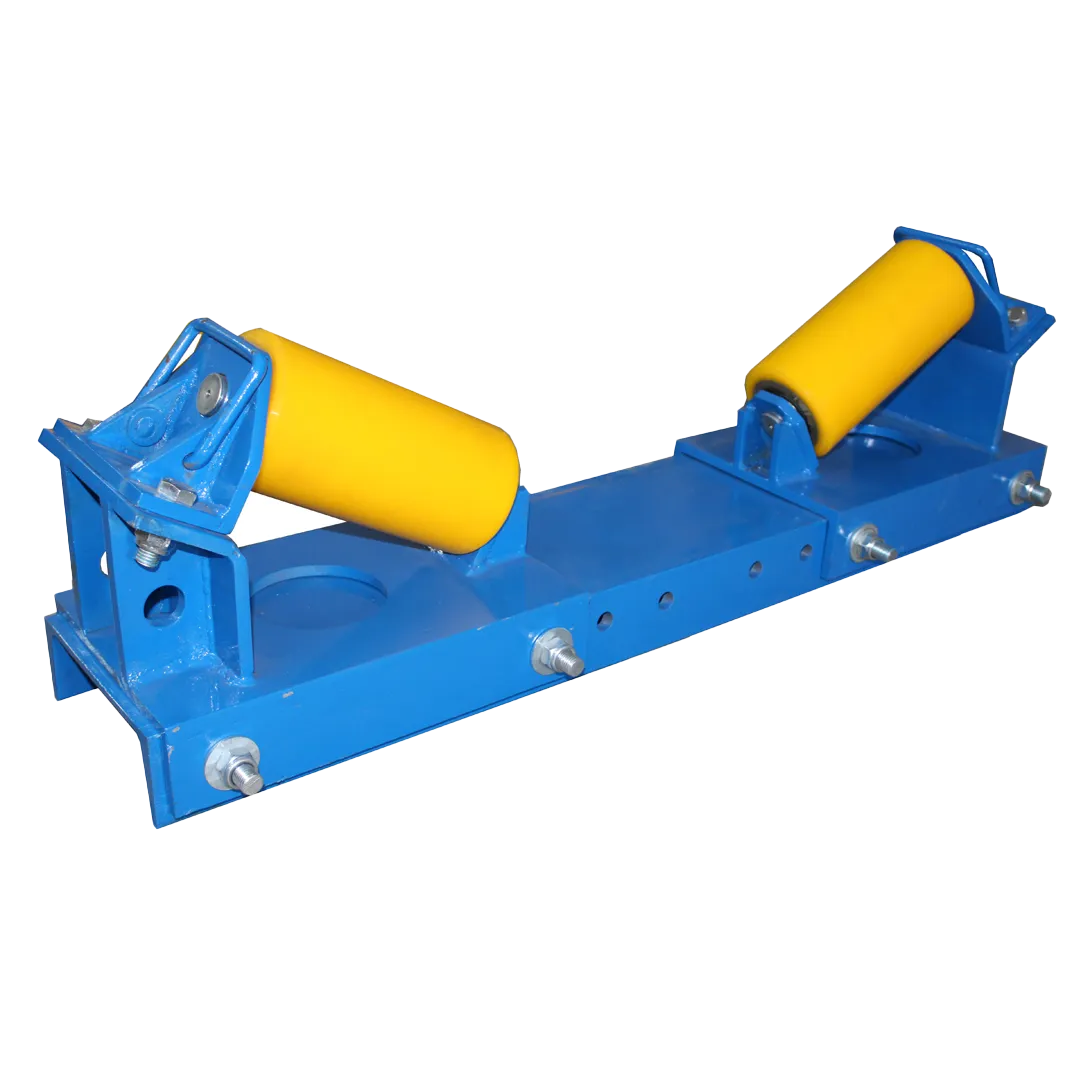

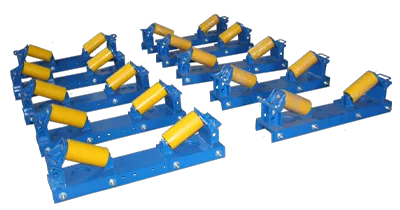

SPM Engineer is a topmost manufacturer company of high-quality Adjustable Rigging Rollers, designed to meet the specific needs of the oil and gas pipeline industry. Our Adjustable Rigging Pipeline Roller come in sizes ranging from 2” To Above, with larger sizes available upon request. These rollers are essential for both installing new pipelines and conducting maintenance work on existing ones. To make sure safe and easy lifting and installation, our adjustable rigging rollers are equipped with Teflon-coated and urethane options and feature side handles. Additionally, the polyurethane coating on our adjustable rigging rollers provides protection to the exterior of pipe coatings during crossings and installations, ensuring the integrity of the pipelines. SPM Engineer is one of the trusted and effective manufacturer of adjustable rigging rollers that can meet all of your pipeline equipment needs.

Three steps are required to adjust the horizontal pipeline roller:-

SPM Engineer is a globally recognized exporter of Adjustable Rigging Roller, with a strong presence in the USA, UAE, Vietnam, Oman, Nigeria, Algeria, and many other countries worldwide. Our commitment to quality and customer satisfaction has made us a preferred choice for clients around the globe. We understand the diverse requirements of different markets and make sure that our products meet international standards. Whether you are looking for a specific size or need customized solutions, SPM Engineer is equipped to deliver adjustable rigging pipeline roller that meet your exact specifications. Our global presence and extensive experience in the oil and gas pipeline industry make us an excellent solution for all of your rigging roller needs.

When it comes to selecting the best adjustable rigging rollers, SPM Engineer stands out as the top choice. Our reputation as a top manufacturer and exporter is built on our solid commitment to quality and innovation. We offer a range of top adjustable rigging pipeline roller products designed to meet the highest standards of performance and durability. Our pipeline equipment products are engineered to provide maximum efficiency and safety, making them ideal for challenging pipeline projects. By choosing SPM Engineer, you benefit from our extensive expertise, superior customer service, and a product lineup that is second to none. Trust us to deliver the best rigging roller solutions adjusted to your specific needs.

We are SPM Engineers, an Ahmedabad-based company with extensive experience in manufacturing and exporting high-quality oil and gas pipeline equipment worldwide. Established in 2016, we offer a comprehensive range of over 100+ oil and gas pipeline equipment products. Our product range includes Pipe Welding Pneumatic Clamps, Pipe Joint Internal Clamp Manual, Pipe Line-Up Clamp Manual (Small Size), Pipe Joint Internal Clamp Hydraulic, Cage Type Pipe Clamp Hydraulic, Cage Type Pipe Clamp Manual, Ratchet Type External Pipe Clamp, and Pipe Joint Clamp 1" to 6" for Oil and Gas Pipeline Construction. Our dedication to quality and innovation has earned us 8+ company awards and the trust of over 400+ happy clients. We are committed to providing the best solutions for our customers' pipeline needs, ensuring efficiency and reliability in every project.

Russia, USA, UAE, Australia, Malaysia, France, Kuwait, Saudi Arabia, Singapore, Tanzania, Switzerland, Qatar, South Korea, Bangladesh, Czech Republic, The Netherlands, Kazakhstan, Mongolia, Nigeria, Vietnam, Oman, Thailand, Mexico, Papua New Guinea, Tunisia, Argentina, Brazil, Canada, India, Japan, Indonesia, New Zealand, Egypt, South Africa, Philippines, Turkey, Greece, Norway, Sweden, Portugal, Spain, Italy, Belgium, Poland, Ireland, Austria, Denmark, Finland, Israel, Iran, Iraq, Lebanon, Jordan, Syria, Libya, Algeria, Morocco, Sudan, Kenya, Uganda, Zimbabwe, Angola, Cambodia, Nepal, Sri Lanka, Myanmar, Afghanistan, Ethiopia, Ghana, Peru, Chile, Bolivia, Honduras, Guatemala, Ecuador, Paraguay, Uruguay, Serbia, Croatia, Bosnia and Herzegovina, Iceland, Luxembourg, Belarus, Ukraine, Lithuania, Latvia, Estonia, Georgia, Armenia, Azerbaijan, Yemen, Bahrain, Cyprus, Maldives, Brunei, Bhutan, Laos, Mauritius, Seychelles, Barbados, Jamaica, Trinidad and Tobago, Fiji, Solomon Islands, Micronesia, Vanuatu, San Marino, Monaco, Liechtenstein, Vatican City, Andorra, Malta, Albania, Moldova, Slovenia, Macedonia, Montenegro, Kosovo, Suriname, Guyana, Belize, Nicaragua, El Salvador, Panama, Costa Rica, The Bahamas, Saint Lucia, Saint Vincent and the Grenadines, Grenada, Dominica, Saint Kitts and Nevis, Antigua and Barbuda, Eswatini, Botswana, Namibia, Lesotho, Zambia, Malawi, Rwanda, Burundi, Djibouti, Eritrea, Somalia, Chad, Central African Republic, Republic of the Congo, Democratic Republic of the Congo, Gabon, Equatorial Guinea, Sao Tome and Principe, Comoros, Guinea, Guinea-Bissau, The Gambia, Liberia, Sierra Leone, Togo, Benin, Burkina Faso, Ivory Coast, Senegal, Mali, Niger, Mauritania, Western Sahara, Mozambique, Madagascar, Turkmenistan, Uzbekistan, Tajikistan, Kyrgyzstan, Palestine, East Timor, Tonga, Samoa, Kiribati, Tuvalu, Nauru, Dominica, Haiti, Cuba, North Korea, China, Pakistan, Hungary, Romania, Bulgaria, Slovakia, Venezuela, Colombia, Laos, South Sudan, Lesotho, Vatican City, Grenada, Saint Lucia, Saint Vincent and the Grenadines, Mongolia, Eswatini, Bhutan, Suriname, Seychelles, Equatorial Guinea, Cape Verde, Liechtenstein, Monaco, Palau, Marshall Islands, Saint Kitts and Nevis, Samoa, and Tuvalu.

Frequently Asked Questions