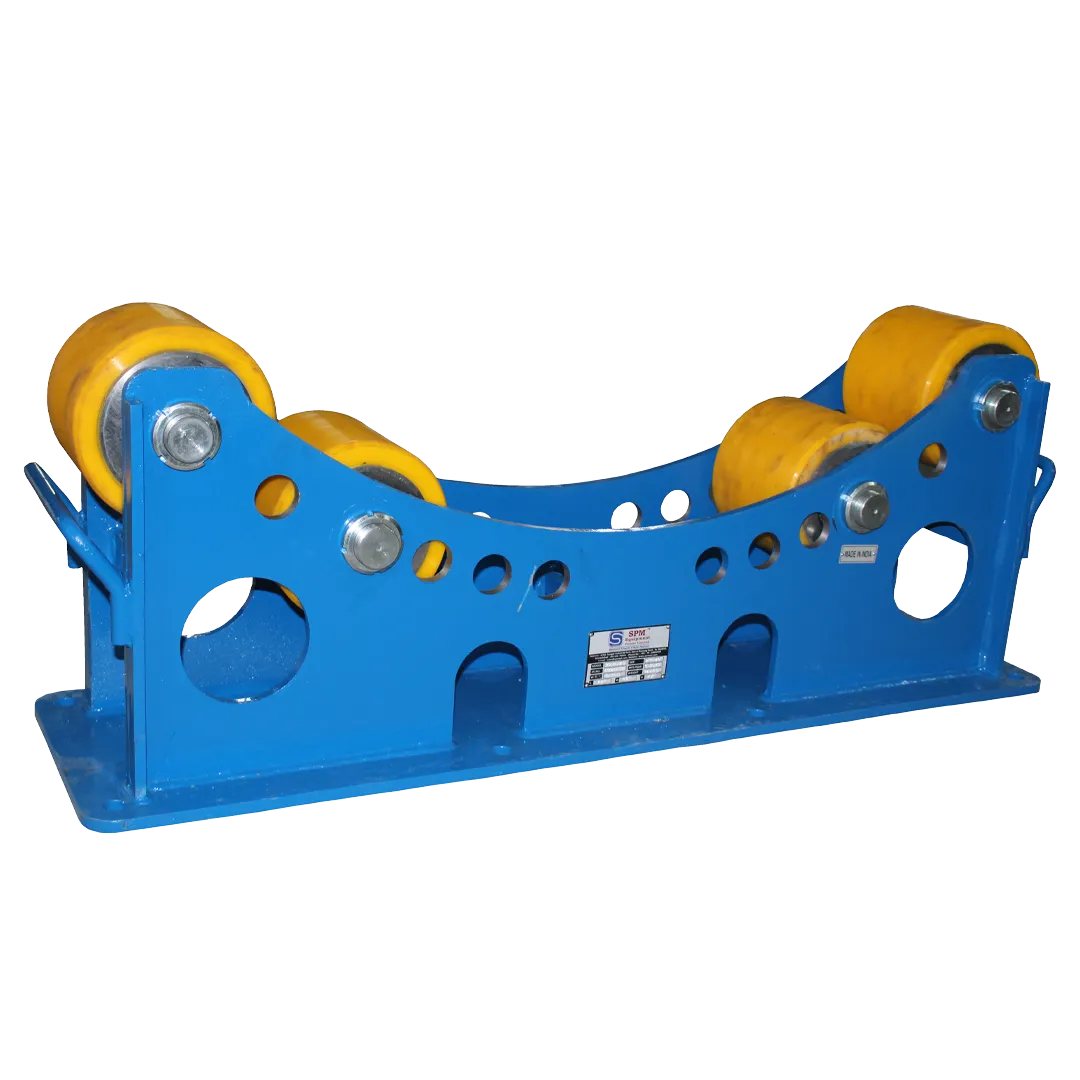

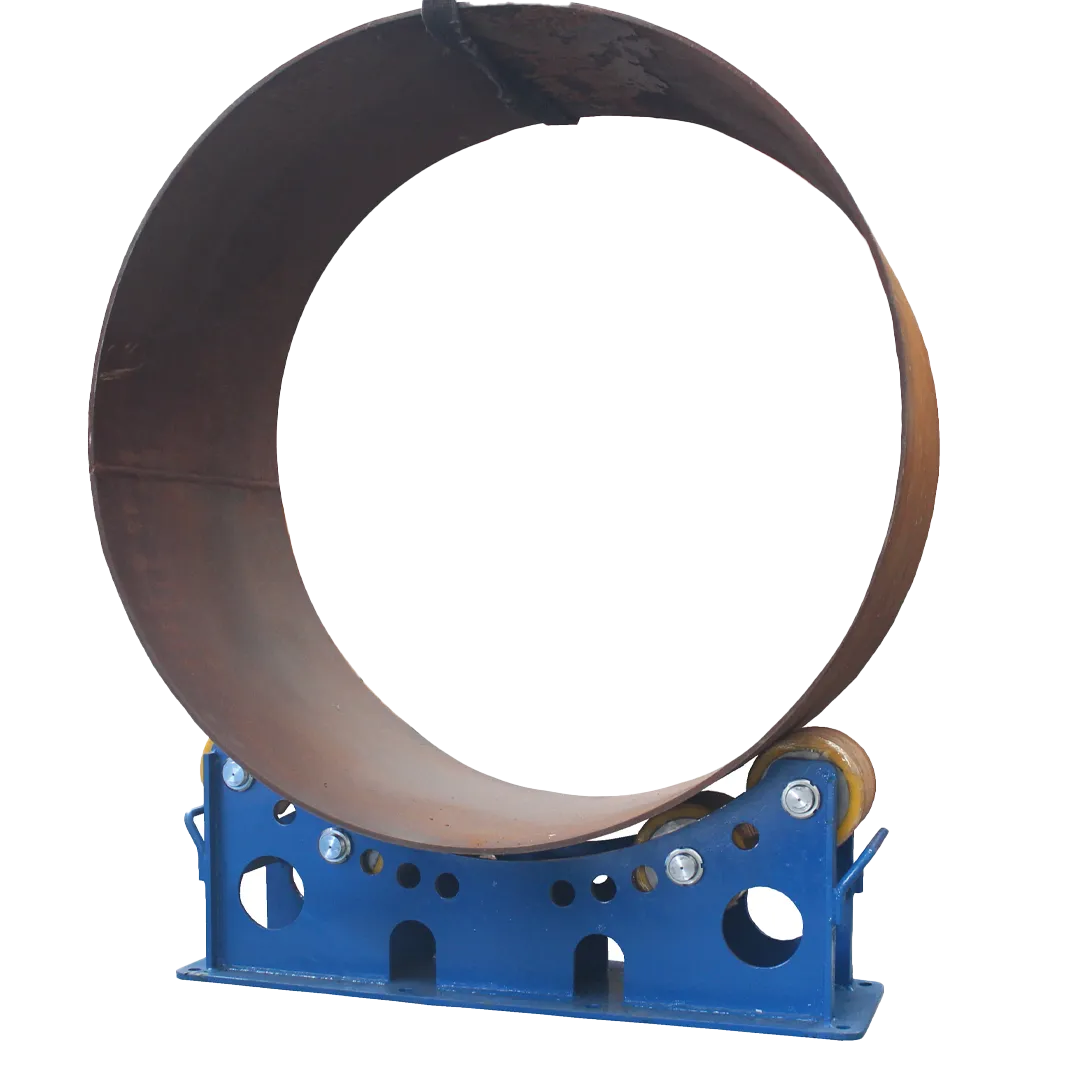

SPM Engineer is the topmost manufacturer company of Pipe Rotator Roller to meet the specific needs of the oil and gas pipeline industry. Our pipe rotators are completely designed to offer full rotation of large offset loads for pipe spooling and welding applications, providing precise positioning and mechanized welding capabilities. These rotators play a crucial role in supplementing the welding process of pipes, containers, tanks, and vessels, as they steady and rotate heavy cylindrical objects during welding. Equipped with adjustable turning rolls, our pipe rotators make sure that the cylinder remains securely positioned throughout the welding process. Our range includes both conventional/manual rotators, consisting of idle rollers only, and automatic welding rotators, featuring both idle and powered sections. Additionally, our self-aligning pipe rotators automatically adapt to the size and shape of the object, minimizing manual handling and enabling efficient welding of oval and asymmetrical shapes. With SPM Engineer's Pipe Rotator Rollers, you can expect best performance and reliability for your pipeline welding needs.

SPM Engineer is recognized as the largest exporter of pipe rotator rollers in USA, UAE, Vietnam, Oman, Nigeria, Algeria, and worldwide. Our commitment to excellence and client satisfaction has established us as reliable providers in the worldwide market. We understand the diverse needs of international clients and make sure that our pipeline equipment meet stringent quality standards. Our top pipe rotator rollers are renowned for their precision, durability, and versatility, making them indispensable for pipeline welding applications worldwide. With our extensive export capabilities and efficient logistics network, we make sure timely delivery of products to clients, regardless of their location. By choosing SPM Engineer as your supplier, you get access to high-quality Pipe Rotator Rollers designed to increase how effective and efficient of your welding operations.

SPM Engineer's pipe rotator rollers are meticulously designed to meet the specific demands of pipeline welding applications, providing full rotation of large offset loads with precision and efficiency. Our pipe rotators are essential for steady and precise welding of cylindrical objects, such as pipes, containers, tanks, and vessels. Equipped with adjustable turning rolls, our rotators make sure secure positioning of the cylinder during welding, minimizing the risk of errors and defects. Whether you require conventional/manual rotators or automatic welding rotators, we offer a range of options to suit your needs. Additionally, our self-aligning pipe rotators adapt automatically to the size and shape of the object, reducing manual handling and enabling efficient welding of irregular shapes. With SPM Engineer, you can trust in the quality, reliability, and performance of our Pipe Rotator Rollers, making us the preferred choice for pipeline welding projects worldwide.

We are SPM Engineers, an Ahmedabad-based company with extensive experience in manufacturing and exporting high-quality oil and gas pipeline equipment worldwide. Established in 2016, we offer a comprehensive range of over 100+ oil and gas pipeline equipment products. Our product range includes Pipe Welding Pneumatic Clamps, Pipe Joint Internal Clamp Manual, Pipe Line-Up Clamp Manual (Small Size), Pipe Joint Internal Clamp Hydraulic, Cage Type Pipe Clamp Hydraulic, Cage Type Pipe Clamp Manual, Ratchet Type External Pipe Clamp, and Pipe Joint Clamp 1" to 6" for Oil and Gas Pipeline Construction. Our dedication to quality and innovation has earned us 8+ company awards and the trust of over 400+ happy clients. We are committed to providing the best solutions for our customers' pipeline needs, ensuring efficiency and reliability in every project.

Russia, USA, UAE, Australia, Malaysia, France, Kuwait, Saudi Arabia, Singapore, Tanzania, Switzerland, Qatar, South Korea, Bangladesh, Czech Republic, The Netherlands, Kazakhstan, Mongolia, Nigeria, Vietnam, Oman, Thailand, Mexico, Papua New Guinea, Tunisia, Argentina, Brazil, Canada, India, Japan, Indonesia, New Zealand, Egypt, South Africa, Philippines, Turkey, Greece, Norway, Sweden, Portugal, Spain, Italy, Belgium, Poland, Ireland, Austria, Denmark, Finland, Israel, Iran, Iraq, Lebanon, Jordan, Syria, Libya, Algeria, Morocco, Sudan, Kenya, Uganda, Zimbabwe, Angola, Cambodia, Nepal, Sri Lanka, Myanmar, Afghanistan, Ethiopia, Ghana, Peru, Chile, Bolivia, Honduras, Guatemala, Ecuador, Paraguay, Uruguay, Serbia, Croatia, Bosnia and Herzegovina, Iceland, Luxembourg, Belarus, Ukraine, Lithuania, Latvia, Estonia, Georgia, Armenia, Azerbaijan, Yemen, Bahrain, Cyprus, Maldives, Brunei, Bhutan, Laos, Mauritius, Seychelles, Barbados, Jamaica, Trinidad and Tobago, Fiji, Solomon Islands, Micronesia, Vanuatu, San Marino, Monaco, Liechtenstein, Vatican City, Andorra, Malta, Albania, Moldova, Slovenia, Macedonia, Montenegro, Kosovo, Suriname, Guyana, Belize, Nicaragua, El Salvador, Panama, Costa Rica, The Bahamas, Saint Lucia, Saint Vincent and the Grenadines, Grenada, Dominica, Saint Kitts and Nevis, Antigua and Barbuda, Eswatini, Botswana, Namibia, Lesotho, Zambia, Malawi, Rwanda, Burundi, Djibouti, Eritrea, Somalia, Chad, Central African Republic, Republic of the Congo, Democratic Republic of the Congo, Gabon, Equatorial Guinea, Sao Tome and Principe, Comoros, Guinea, Guinea-Bissau, The Gambia, Liberia, Sierra Leone, Togo, Benin, Burkina Faso, Ivory Coast, Senegal, Mali, Niger, Mauritania, Western Sahara, Mozambique, Madagascar, Turkmenistan, Uzbekistan, Tajikistan, Kyrgyzstan, Palestine, East Timor, Tonga, Samoa, Kiribati, Tuvalu, Nauru, Dominica, Haiti, Cuba, North Korea, China, Pakistan, Hungary, Romania, Bulgaria, Slovakia, Venezuela, Colombia, Laos, South Sudan, Lesotho, Vatican City, Grenada, Saint Lucia, Saint Vincent and the Grenadines, Mongolia, Eswatini, Bhutan, Suriname, Seychelles, Equatorial Guinea, Cape Verde, Liechtenstein, Monaco, Palau, Marshall Islands, Saint Kitts and Nevis, Samoa, and Tuvalu.

Frequently Asked Questions