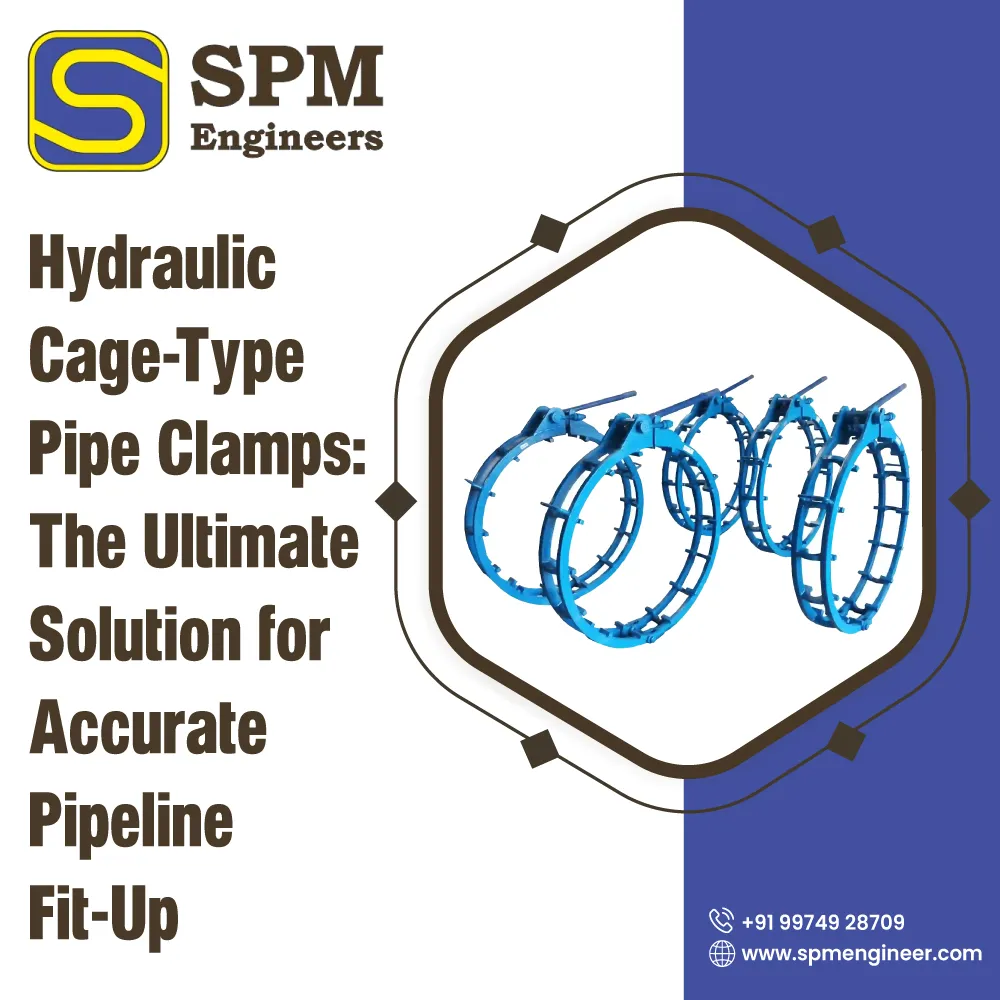

Precision in pipeline construction defines project quality, efficiency, and safety. For contractors and engineers across the oil, gas, water, and industrial pipeline sectors, achieving perfect alignment during welding is a non-negotiable standard. The Hydraulic Cage-Type Pipe Clamp is a groundbreaking solution that simplifies pipeline alignment and delivers exceptional accuracy during fit-up operations.

Engineered to handle heavy-duty pipes and designed for ease of operation, the cage type pipe clamp hydraulic system offers consistent, secure, and rapid alignment of pipes before welding. This advanced clamping mechanism eliminates the inefficiencies of manual alignment, making it a preferred choice among professionals in India and worldwide.

In this detailed guide, we explore the importance, working principle, applications, and global demand for hydraulic cage type pipe clamps, highlighting why SPM Engineers is one of the leading manufacturers and exporters in this domain.

What Is a Hydraulic Cage-Type Pipe Clamp?

A Hydraulic Cage-Type Pipe Clamp is a precision tool used to align pipes end-to-end during welding and fit-up operations. Built with a strong cage frame and powered by hydraulic pressure, it positions pipes accurately in a circular formation, allowing welders to achieve perfect joint geometry.

The cage design provides 360-degree coverage, keeping both pipe sections firmly in position. Unlike manual clamps, which require physical adjustments, the cage type pipe clamp hydraulic system uses hydraulic cylinders to expand and contract, reducing alignment time and enhancing operational accuracy.

These clamps are indispensable for large-diameter and heavy-wall pipes used in cross-country pipelines, refineries, and industrial projects where speed, accuracy, and safety are top priorities.

How Does a Hydraulic Cage-Type Pipe Clamp Work?

The working mechanism of a cage type pipe clamp hydraulic system combines strength, precision, and hydraulic engineering. Here’s how it functions step-by-step:

- Setup: The clamp is positioned around the two pipe ends.

- Hydraulic Activation: Hydraulic pressure is applied through a manual or motorized power pack.

- Alignment: The clamp’s shoes expand, pressing evenly against the pipe’s outer surface to align the pipes perfectly.

- Locking: Once aligned, the pressure is maintained while tack welding is performed.

- Release: After welding, the hydraulic pressure is released, and the clamp is removed.

This efficient mechanism helps welders achieve uniform root gaps and precise alignment across various pipe diameters. SPM Engineers’ hydraulic cage type pipe clamps are designed to maintain consistent performance even in rugged environments.

Key Features of Hydraulic Cage-Type Pipe Clamps

SPM Engineers, a trusted cage type pipe clamp hydraulic manufacturer, has engineered its clamps to deliver unmatched reliability and durability. Below are some of the key features that make these clamps stand out:

- Heavy-Duty Hydraulic System: For powerful and stable operation on large pipes.

- High-Strength Steel Construction: Offers durability under high pressure and tough field conditions.

- Compact and Modular Design: Easy to transport and assemble on-site.

- Precision Machined Components: Guarantee uniform clamping and perfect circular alignment.

- Quick Setup and Release Mechanism: Reduces downtime between welds.

- Compatibility: Suitable for carbon steel, stainless steel, and alloy pipelines.

- Global Export Standards: Used across India, Oman, UAE, Vietnam, Nigeria, and Algeria.

These advanced features make SPM Engineers’ hydraulic cage type pipe clamp a trusted choice among pipeline contractors seeking productivity and accuracy.

Applications of Hydraulic Cage-Type Pipe Clamps

The hydraulic cage type pipe clamp is used in a variety of industries that require high-precision welding operations. Key applications include:

- Oil & Gas Pipelines: For cross-country and offshore pipeline installations.

- Petrochemical Industries: For precise fit-up of process pipes.

- Refineries & Power Plants: Where pipe alignment accuracy is critical.

- Water Transmission Lines: For heavy-duty and long-distance pipelines.

- Industrial Fabrication Units: For large-diameter pipe welding projects.

Whether it’s cage type pipe clamp hydraulic in UAE, Vietnam, or Nigeria, SPM Engineers delivers consistent global performance for every project requirement.

Benefits of Hydraulic Cage-Type Pipe Clamps

- Superior Pipe Alignment: The hydraulic cage type pipe clamp aligns pipes internally and externally with exceptional accuracy, minimizing weld distortion and enhancing joint strength.

- Faster Fit-Up: Hydraulic activation speeds up alignment, reducing the time required for each joint compared to manual clamping systems.

- Enhanced Safety: Operators handle pipes more safely as the hydraulic pipe clamps heavy duty mechanism minimizes physical lifting and positioning effort.

- Cost-Effective Operations: By improving welding efficiency and reducing rework, contractors save both time and money on large-scale projects.

- Global Compatibility: From cage type pipe clamp hydraulic in Oman to cage type pipe clamp hydraulic in Algeria, these clamps operate effectively across diverse environments, offering international performance standards.

These advantages make SPM Engineers’ hydraulic cage type pipe clamp the preferred choice for professionals worldwide.

Why Hydraulic Clamps Outperform Manual Systems

Manual clamps may be cheaper upfront, but they fall short in terms of productivity and precision. The cage type pipe clamp hydraulic model offers superior consistency and reliability through:

| Feature | Manual Clamp | Hydraulic Cage-Type Clamp |

|---|---|---|

| Alignment Accuracy | Moderate | High Precision |

| Speed of Operation | Slow | Fast and Efficient |

| Safety | Labor-Intensive | Safe Hydraulic Operation |

| Pipe Size Compatibility | Limited | Wide Range |

| Consistency | Varies by Operator | Uniform Every Time |

For contractors handling complex welding operations, hydraulic systems are the smart investment.

Maintenance Tips for Long-Lasting Performance

To maintain optimal functionality of your hydraulic cage type pipe clamp, follow these best practices:

- Regularly inspect hydraulic hoses and fittings for leaks.

- Clean the clamp after each use to remove welding debris.

- Lubricate moving parts to prevent corrosion.

- Store clamps in a dry environment when not in use.

- Check hydraulic fluid levels and seals periodically.

Routine maintenance maximizes performance and extends service life, keeping your hydraulic pipe clamps heavy duty reliable in all conditions.

Why Choose SPM Engineers

SPM Engineers stands as a leading cage type pipe clamp hydraulic manufacturer, offering innovative solutions designed for modern pipeline construction. Our hydraulic clamps are engineered for strength, reliability, and accuracy, helping industries achieve faster project completion with zero compromise on quality.

With decades of experience in pipeline equipment manufacturing, SPM Engineers offers both standard and customized hydraulic cage type pipe clamps to meet diverse project needs. Our presence as a cage type pipe clamp hydraulic exporter extends to Oman, UAE, Vietnam, Nigeria, and Algeria — where contractors rely on our products for consistent performance under demanding conditions.

When you partner with SPM Engineers, you gain access to world-class manufacturing standards, prompt technical support, and long-lasting machinery designed for superior field results.

Conclusion

The Hydraulic Cage-Type Pipe Clamp represents the next level of accuracy and productivity in pipeline welding fit-up. From heavy-duty hydraulic performance to precise pipe centering, these tools play an essential role in building strong and efficient pipeline systems.

Backed by innovation and craftsmanship, SPM Engineers continues to lead as a global cage type pipe clamp hydraulic manufacturer and exporter, providing cutting-edge tools that meet industry expectations worldwide.

For more information about Hydraulic Cage-Type Pipe Clamps and related welding fit-up tools, contact SPM Engineers to discuss your project requirements. Call us today at +91 9974928709 or email us at info@spmengineer.com.